1. Introduction

Woodworking has been a timeless craft, cherished for its ability to transform raw timber into functional and artistic creations. Yet, in the age of technology, woodworking has evolved. One of the most exciting advancements in this craft is the integration of wood laser cutters. In this comprehensive guide, we’ll take you on a journey to explore the world of wood laser cutters and how they can revolutionize your woodworking experience.

i. Overview of Laser Cutters

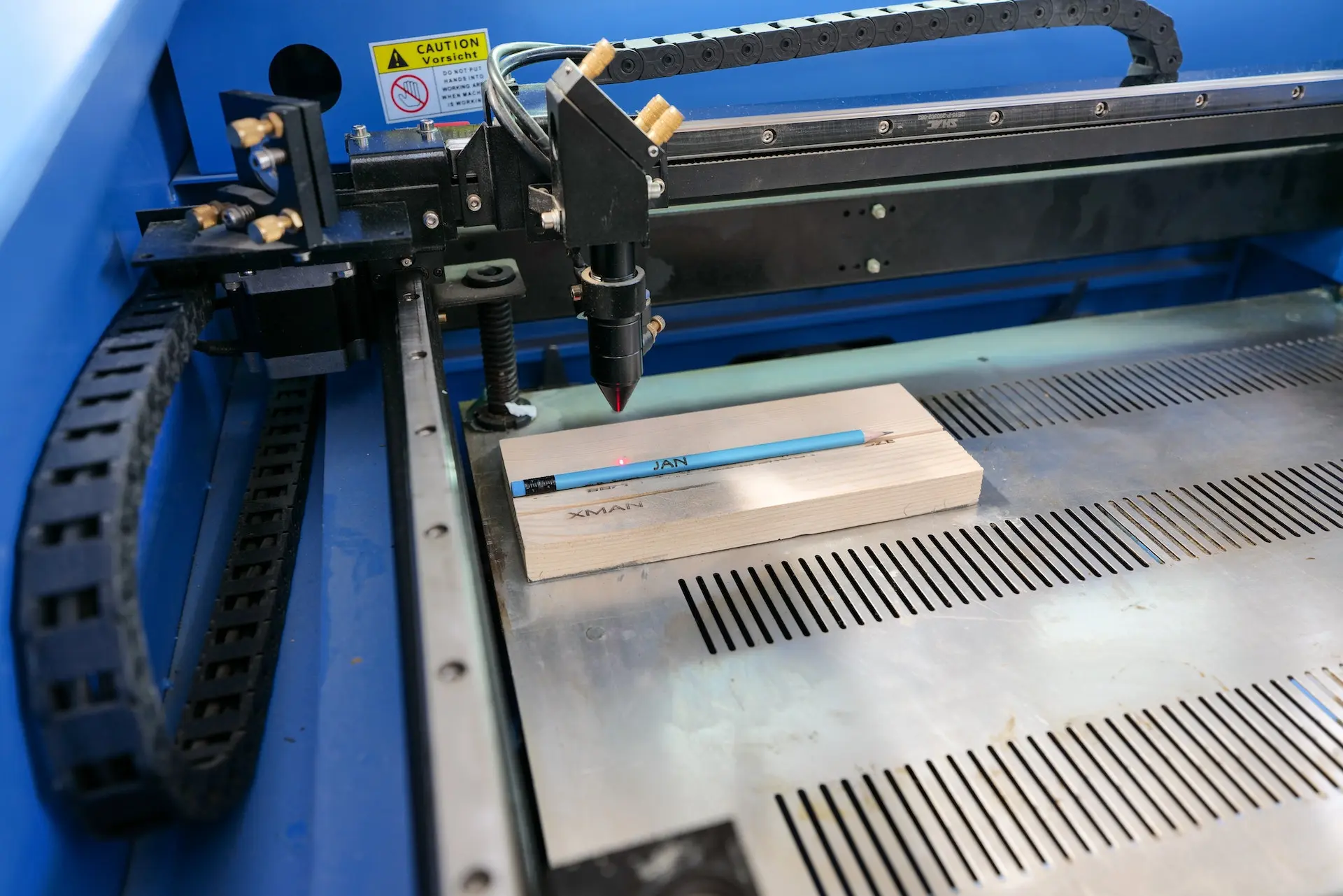

Wood laser cutters, often referred to as laser engraving machines, are a marvel of modern engineering. They bring together the precision of technology and the beauty of wood, enabling woodworkers to create intricate designs, flawless joints, and personalized masterpieces that were once considered unattainable.

ii. Why Woodworkers Should Consider Using Laser Cutters

Wood laser cutters open up a world of possibilities for both beginners and seasoned woodworkers. These machines provide an avenue for pushing the boundaries of your creativity and craftsmanship. Whether you’re making intricate inlays, personalized gifts, or mass-producing wooden products, laser cutters offer unparalleled precision and speed.

Before continuing, have a look at DIY Montreal’s first laser cutter decision making. Do you need one?

iii. Importance Of This Guide

Navigating the world of wood laser cutters can be daunting, but this guide aims to simplify the process. With a focus on clarity, authoritative information, and a commitment to citing sources, we’re here to be your trusted companion on this exciting journey. By the end of this guide, you’ll have the knowledge and confidence to incorporate wood laser cutters into your woodworking projects, and perhaps even redefine the limits of your creativity.

Did you know? Laser engraving for wood (synonym name to cutting) can be thought of as an alternative to wood paiting.

2. Understanding Laser Cutters

Wood laser cutters are a powerful tool in the arsenal of modern woodworkers. These machines utilize a high-powered laser to cut, engrave, and shape wood with precision. Understanding the fundamentals of wood laser cutters is the first step in harnessing their potential.

i. What Is A Wood Laser Cutter?

A wood laser cutter is a machine that employs a focused laser beam to cut or engrave wood. This is achieved by focusing the laser on a specific point on the wood’s surface. When the laser interacts with the wood, it either vaporizes or burns the material, leaving behind a clean and precise cut or an intricately detailed engraving.

The level of control offered by wood laser cutters is unparalleled. Woodworkers can define intricate patterns, shapes, and cuts, making it a versatile tool in the hands of both beginners and seasoned artisans. Whether you’re creating intricate wooden jewelry, custom signage, or decorative inlays, a wood laser cutter empowers you to achieve results that were previously time-consuming and difficult to attain.

ii. How Do Wood Laser Cutters Work?

Wood laser cutters employ a fascinating process known as “vaporization cutting“. The high-energy laser beam generates intense heat when it strikes the wood. This heat is so concentrated that it causes the wood to vaporize instantly, resulting in a precise and narrow kerf. This process ensures minimal material wastage and leaves you with impeccably clean edges.

In the realm of engraving, laser cutters utilize a different approach. Instead of vaporizing the wood, they gradually remove material layer by layer, allowing you to create intricate designs, patterns, and text. This meticulous process can add a level of detail and personalization to your woodworking projects that would be incredibly challenging to achieve through traditional methods.

Understanding these fundamental principles of wood laser cutters is the first step in harnessing their potential for your woodworking projects. These machines offer precision and versatility that can take your craft to the next level.

iii. Different Types Of Laser Cutting Machines

There are various types of laser cutting machines, including CO2, fiber laser cutting machines, and diode lasers. Each type has its unique strengths and is suitable for different applications.

If reading is not for you, I recommend you watch this next video, it is one of the most comprehensive compilations of laser cutters for any budget we have seen.

a. CO2 Laser Cutters

CO2 laser cutters are among the most commonly used machines in woodworking. They employ a carbon dioxide gas mixture as the laser source. These machines are known for their versatility and are suitable for cutting, engraving, and etching various materials, including wood. CO2 laser cutters excel in producing detailed and intricate designs, making them an ideal choice for artistic and decorative woodworking projects.

b. Fiber Laser Cutters

Fiber laser cutters utilize a fiber-optic laser source, which is particularly well-suited for cutting metal materials. However, they can also cut wood with precision. These machines are known for their speed and efficiency, making them an excellent choice when you need to process materials quickly and with accuracy.

c. Diode Laser Cutters

Diode laser cutters are compact and cost-effective machines that are suitable for engraving and marking rather than heavy-duty cutting. While they might not be the first choice for extensive woodworking projects, they are ideal for adding personalized details and designs to wooden items, like personalized gifts and crafts.

Choosing the right type of laser cutter depends on your specific woodworking needs and the materials you plan to work with. CO2 laser cutters are versatile and suitable for most woodworking applications, while fiber and diode lasers have their niches in specialized projects. Understanding the capabilities and limitations of each type helps you make an informed decision when investing in a wood laser cutter.

iv. Advantages Of Using Wood Laser Cutters

Wood laser cutters offer several advantages, including unparalleled precision, speed, and the ability to cut intricate designs. They are versatile and suitable for various woodworking projects.

a. Precision and Accuracy

One of the most prominent advantages of laser cutters is their unmatched precision and accuracy. These machines can cut and engrave wood with a level of detail that’s nearly impossible to achieve through traditional woodworking methods. The focused laser beam ensures clean, sharp edges, even on intricate designs. This precision is invaluable for woodworkers who demand high-quality results in their projects.

b. Versatility

Laser cutters can cut and engrave a wide range of materials, from wood and acrylic to fabric and metal. In woodworking, this means you can use laser cutters for intricate inlays, precise joinery, and customized designs. The ability to work with different materials expands the possibilities and applications in woodworking projects.

c. Speed and Efficiency

Laser cutters can complete tasks in a fraction of the time it would take using traditional woodworking. This speed not only increases productivity but also allows for the production of high-quality items in larger quantities. If you’re engaged in a woodworking as a business, this advantage is particularly valuable. You may also consider a larger wood cutter, not necessarily for its size, but for the room you will have as you switch in and out of different pieces.

d. Repeatability

Laser cutters offer exceptional repeatability. Once you’ve perfected a design, you can replicate it with the same precision, whether you’re making a single piece or a hundred identical items. This is advantageous if you need consistent results.

e. Reduced Material Waste

Traditional woodworking often results in significant material waste due to kerf width and human error. Laser cutters, on the other hand, have minimal kerf widths and are guided by precise computer-controlled systems, which significantly reduce material wastage. This is not only cost-effective but also environmentally friendly.

f. Intricate and Complex Designs

Laser cutters excel at handling complex and intricate designs. They can create delicate filigree patterns, detailed engravings, and intricate interlocking pieces. This capability is particularly valuable for woodworking projects that require precision, such as intricate marquetry, jigsaw puzzles, and personalized engraving.

The advantages of laser cutters make them an invaluable tool for woodworkers, artisans, and manufacturers alike. Their precision, versatility, speed, repeatability, and ability to reduce material waste have transformed the woodworking industry, enabling woodworkers to push the boundaries of their craft and create stunning, detailed, and high-quality pieces.

v. Disadvantages And Limitations

While wood laser cutters are incredibly versatile, they do have limitations. Thick woods may be challenging to cut, and excessive heat can lead to charring. Understanding these limitations is crucial for successful laser cutting.

a. Cost

High-quality laser cutting machines can be quite expensive, which might deter hobbyist woodworkers or those with budget constraints. Additionally, ongoing maintenance and replacement parts can add to the long-term costs. Not to brag, but our best budget laser cutters article is among the top in the web.

b. Limited Cutting Depth

While they excel at creating precise, shallow cuts, they may struggle with thicker pieces of wood. This limitation can be frustrating for woodworkers looking to cut through thicker materials for certain projects.

c. Fire Hazard

Laser cutters generate intense heat, which can pose a fire hazard, particularly if they are not properly maintained or used without caution. Wood is flammable, and if the laser cutter generates excessive heat or encounters imperfections in the material, it can lead to charring or even ignite the wood.

d. Learning Curve

Using laser cutters effectively requires a learning curve. Understanding the machine’s software, settings, and safety precautions can take time.

e. Regular Maintenance

To ensure consistent performance and longevity, laser cutters require regular maintenance. Cleaning optics, aligning mirrors, and replacing components are part of routine upkeep. Neglecting maintenance can lead to diminished quality of cuts and potential machine failures.

Understanding these disadvantages is crucial for anyone considering the integration of wood laser cutters into their woodworking toolkit. While they offer remarkable precision and efficiency, it’s essential to address the costs, safety concerns, and material limitations to use these machines effectively and safely.

3. Essential Wood Laser Cutter Components

i. Laser Source and Power

At the heart of any laser cutter is the laser source itself. It’s what generates the intense beam of light used for cutting. The power of the laser source is measured in watts. When working with wood, a CO2 laser is a popular choice, typically ranging from 30 to 400 watts. The power you need depends on the thickness and type of wood you plan to cut. For intricate details and fine cuts, lower wattage might suffice, but thicker woods require more power.

ii. Laser Optics

Laser optics are responsible for focusing the laser beam onto your workpiece with precision. These optical components include lenses and mirrors. High-quality optics ensure that the laser remains accurate and consistent. Regular cleaning and maintenance are essential to prevent residue buildup, which can affect the quality of your cuts.

iii. Motion Control System

The motion control system guides the laser head over your workpiece. It consists of motors, belts, and rails. The precision and speed of this system affect the quality and efficiency of your cuts. Modern laser cutters often use digital controllers, which allow you to create intricate designs and patterns with ease.

iv. Worktable and Bed

The worktable provides a stable surface for your wood. Depending on the laser cutter’s design, it may have a fixed bed or an adjustable one. An adjustable bed is versatile, accommodating various material thicknesses. For precise results, ensure your wood is flat and level on the worktable.

v. Exhaust System

The exhaust system is crucial for removing smoke, fumes, and debris produced during the cutting process. It consists of a fan, ducting, and filters. Proper ventilation not only keeps your workspace clean but also safeguards your health. Ensure the exhaust system is adequately sized for your laser cutter.

vi. Cooling System

Laser sources generate a significant amount of heat, which can damage the components if not managed properly. A cooling system, often involving water or air, helps dissipate this heat. Regularly check the coolant levels and ensure that the cooling system is functioning optimally.

vii. Safety Features

Safety should be a top priority when working with a wood laser cutter. These machines often come with features like interlocks, emergency stop buttons, and protective enclosures. Always wear appropriate safety gear, such as laser safety glasses, to protect your eyes from the intense laser light.

4. Choosing the Right Laser Cutter

i. Determining Your Specific Needs

Before diving into the world of wood laser cutters, it’s crucial to assess your specific requirements. Different projects and objectives demand different machines. Here’s a list of questions to help you determine your needs:

- What materials will you primarily work with? (e.g., wood types, thickness)

- Do you need intricate detailing or general cutting capabilities?

- Is speed a critical factor for your projects?

- What is the typical size of your workpieces?

- Will you need portability, or is a stationary machine acceptable?

- Are you a hobbyist or a professional woodworker with high-volume production needs?

Consider creating a checklist of your specific needs to guide your decision.

ii. Budget Considerations

Your budget is a significant factor when choosing a wood laser cutter. These machines come in a range of prices, so it’s essential to find a balance between your needs and your budget. Here’s a breakdown of costs to consider:

- Initial machine cost: This includes the laser cutter itself, which can range from a few hundred to tens of thousands of dollars, depending on the features and power.

- Operating costs: You’ll need to factor in ongoing expenses, such as electricity, maintenance, and replacement parts.

- Software and accessory costs: Don’t forget to account for software licenses and any additional accessories you may require.

It’s wise to create a budget spreadsheet to ensure you’re making a well-informed financial decision.

iii. Considerations for Different Wood Types

Wood laser cutters can handle various wood types, but different lasers may be better suited for specific materials. Consider the following:

- Hardwood vs. Softwood: Some laser cutters are more effective with one type over the other. Research which wood types your chosen machine can work with efficiently.

- Plywood and MDF: If you frequently use these composite materials, ensure your laser cutter can cut through them cleanly without excessive charring.

- Exotic Woods: For intricate designs on expensive or exotic woods, precision and minimal waste are key. Look for a machine that can deliver such results.

iv. Evaluating the Cutting Area

The size of the cutting area or work envelope is a critical factor. It determines the maximum dimensions of your workpieces. Consider your typical project size and ensure the laser cutter can accommodate it. Here’s a quick table to help you evaluate the cutting area:

| Machine Model | Cutting Area | Suitable for |

|---|---|---|

| Mini | 12″ x 18″ | Small projects, engraving |

| Midi | 24″ x 36″ | Medium-sized projects, signage |

| Full-size | 48″ x 96″ | Large-scale projects, furniture |

The choice of cutting area depends on your intended applications.

v. Software Compatibility

Your laser cutter is only as good as the software that controls it. Consider the compatibility with design software, as well as the user-friendliness of the provided software. Here’s a list of software-related considerations:

- Design Software Compatibility: Ensure the laser cutter can work with popular design software like Adobe Illustrator, CorelDRAW, or AutoCAD.

- User Interface: Check if the machine’s control software is user-friendly and offers the features you need for your projects.

- Updates and Support: Does the manufacturer provide regular software updates and customer support?

Remember that user-friendly software can greatly enhance your laser cutting experience and the quality of your projects.

By carefully evaluating these factors, you’ll be well on your way to choosing the right wood laser cutter that aligns with your specific needs and budget. It’s a significant investment, and taking the time to make an informed decision will undoubtedly pay off in your woodworking journey.

5. Safety Precautions and Best Practices

i. Laser Safety Guidelines

- Laser Safety Glasses: Invest in high-quality laser safety glasses that are specific to the wavelength of your laser cutter. These glasses protect your eyes from the intense laser light.

- No Direct Viewing: Never look directly into the laser beam, even with safety glasses on. The concentrated light can cause severe eye damage.

- Interlocks and Safety Systems: Ensure your laser cutter is equipped with interlocks and safety features. These systems should prevent the machine from operating if safety enclosures are open or if there are other hazardous conditions.

- Training: Properly train anyone using the laser cutter. They should understand the machine’s operation, emergency procedures, and safety protocols.

- Emergency Stop: Familiarize yourself with the emergency stop button on your wood laser cutter. It should be easily accessible and used in case of any unexpected issues.

ii. Proper Ventilation and Filtration

Effective ventilation and filtration are essential to remove harmful fumes and smoke produced during laser cutting.

- Exhaust System: Ensure your laser cutter is connected to an exhaust system with adequate airflow to carry away fumes and particulates. Regularly check and clean the exhaust ducts to prevent clogs.

- Filtration Unit: Consider using a filtration unit, especially if you can’t exhaust the fumes outdoors. These units use filters to capture and remove particles and odors. Replace or clean the filters as recommended by the manufacturer.

- Ventilation Design: Design your workspace with proper ventilation in mind. Position the laser cutter near an exterior wall or window for efficient exhaust.

- Air Quality Monitoring: Install an air quality monitor in your workspace to ensure that fume levels remain within safe limits.

iii. Personal Protective Equipment (PPE)

Using the right personal protective equipment is crucial for your safety.

- Laser Safety Glasses: We mentioned this earlier, but it’s worth repeating. Always wear laser safety glasses that match the laser’s wavelength.

- Protective Clothing: Wear non-flammable, tight-fitting clothing to reduce the risk of catching fire or getting caught in moving parts.

- Respirator: If you work with materials that produce harmful vapors, consider using a respirator with appropriate filters.

- Gloves: Heat-resistant gloves are a good idea to protect your hands when handling materials that have been cut or engraved.

iv. Fire Prevention Measures

Laser cutters generate heat and can pose a fire hazard. Taking fire prevention measures is crucial.

- Fire Extinguishers: Have fire extinguishers within reach of the laser cutter. Ensure they are suitable for extinguishing fires involving electrical equipment.

- Material Compatibility: Be aware of the materials you’re using. Some materials are more prone to catching fire, so adjust your laser cutter’s settings accordingly.

- Material Removal: After each cutting session, remove any scrap material from the bed and work area to prevent accidental ignition.

v. Maintenance and Cleaning

Proper maintenance and cleaning help ensure the safe and efficient operation of your laser cutter.

- Regular Cleaning: Regularly clean the laser optics, lens, and mirrors. Dust and residue can affect cutting quality.

- Cooling System: Check and maintain the cooling system to prevent overheating. Ensure the coolant levels are sufficient and that there are no leaks.

- Exhaust System Inspection: Inspect the exhaust system for leaks and blockages. Ensure it’s effectively removing fumes.

- Electrical Safety: Periodically inspect the electrical components for signs of wear or damage. Loose wires, frayed cords, or damaged outlets can pose a risk.

- Lubrication: If your laser cutter has moving parts that require lubrication, follow the manufacturer’s recommendations for proper lubrication intervals.

By following these safety precautions and best practices, you can minimize the risks associated with laser cutters and enjoy your woodworking projects with confidence. Remember, safety is paramount, and it should never be compromised for the sake of convenience or expediency.

6. Software And Design For Wood Laser Cutting

i. Overview of Laser Cutting Software

Before you start your laser cutting journey, it’s essential to grasp the software used to control the machine. Laser cutting software allows you to create, edit, and send designs to the laser cutter. Here’s a quick overview:

| Software | Description |

|---|---|

| CorelDRAW | Popular vector design software that’s compatible with many laser cutters. |

| Adobe Illustrator | Another powerful vector design software commonly used in laser cutting. |

| AutoCAD | Ideal for creating precise technical drawings and 2D designs. |

| Trotec JobControl | Proprietary software for Trotec laser cutters, offering advanced features. |

Choose software that aligns with your design preferences and laser cutter compatibility.

ii. Preparing Your Design Files

Your design files are the blueprints for your laser cutting project. Here are steps to prepare your files:

- Start with Vector Graphics: Laser cutters work with vector files, which consist of lines and shapes. Convert any raster images (like photos) to vectors if needed.

- Set Your Design Dimensions: Ensure your design’s dimensions match the material size you plan to use on the laser cutter.

- Design in Layers: Organize your design in layers. This can help you control the order in which elements are cut or engraved.

iii. Importing and Editing Designs

Once your design is ready, you’ll need to import it into your laser cutting software and make any necessary adjustments.

- Importing: Open your design software, and import your design file. Verify that the design appears correctly in the software’s workspace.

- Adjustments: Use the software’s tools to make any edits or modifications. You can scale, rotate, and manipulate elements as needed.

iv. Optimizing Settings for Different Wood Types

Wood comes in various types and thicknesses, and optimizing your laser cutter settings for each type is essential. Here’s a quick reference table:

| Wood Type | Cutting Speed | Power | Frequency | Notes |

|---|---|---|---|---|

| Plywood | 10-30 mm/s | 80-90% | 500 Hz | Adjust settings based on the number of ply layers. |

| MDF | 10-20 mm/s | 80-90% | 1000 Hz | Low frequency for clean edges. |

| Oak | 5-15 mm/s | 80-90% | 1000 Hz | Adjust power for different thicknesses. |

| Cherry | 5-20 mm/s | 70-80% | 1000 Hz | Lower power for lighter engraving. |

These are general settings, and it’s important to conduct test cuts to find the optimal parameters for your specific wood and laser cutter.

v. Common Design Mistakes to Avoid

To ensure your laser-cut designs are flawless, steer clear of these common design mistakes:

- Unclosed Paths: Check for any unclosed paths in your vector design, which can lead to incomplete cuts.

- Inconsistent Line Thickness: Maintain consistent line thickness for more uniform cutting and engraving.

- Overlapping Paths: Overlapping lines can result in double cutting, affecting the quality of your design.

- Improper Line Colors: Assign distinct colors to your design elements to control the laser’s actions, such as cutting, engraving, or skipping.

By understanding the software, preparing your designs, and optimizing settings for different wood types, you’ll be well on your way to creating impressive laser-cut projects. Avoiding common design mistakes is the final step to ensure your creations are impeccable. Enjoy the art of laser cutting in woodworking!

7. Laser Cutting Techniques for Wood

i. Vector Cutting

Vector cutting is a fundamental laser cutting technique that involves following vector paths to cut through the wood. It’s perfect for creating intricate shapes, precise joints, and detailed inlays. Here’s how it works:

- Design in Vectors: Use vector design software to create a design, where lines define the path for cutting.

- Custom Cuts: Vector cutting is ideal for creating intricate joinery like dovetail or finger joints and precise inlays.

ii. Raster Engraving

Raster engraving is a technique that involves using the laser to burn or etch the surface of the wood. It’s great for adding intricate patterns, text, or images to your projects:

- Grey Scale Images: Raster engraving can reproduce grey scale images with varying depths, creating detailed designs.

- Customization: Add personalized engravings to signs, boxes, or decorative wooden items.

iii. 3D Engraving

Taking engraving to the next level, 3D engraving allows you to create three-dimensional textures and reliefs on wood. It’s a technique that adds depth and dimension to your projects:

- Height Maps: Use height maps in your design software to control the laser’s power and speed for various depths.

- Realistic Textures: Achieve realistic wood grains, stone textures, or intricate sculptures with 3D engraving.

iv. Inlay and Marquetry

Inlay and marquetry are techniques that involve fitting precisely cut pieces of wood into corresponding recesses in a base wood piece. This technique allows you to create intricate patterns and designs:

- Design Patterns: Create geometric or figurative patterns using different wood species for contrast.

- Precision and Detail: Inlay and marquetry require meticulous cutting and fitting, but the results are stunning.

v. Joinery and Interlocking Parts

Laser cutting is excellent for creating intricate joinery and interlocking parts in woodworking projects:

- Precise Joints: Laser-cut joints like dovetails, tenons, and mortise and tenon joints fit together with remarkable precision.

- Reduced Assembly Time: Interlocking parts designed with a laser cutter often require minimal gluing or fasteners, speeding up assembly.

8. Projects and Inspiration

i. Beginner Projects

- Coasters: Craft wooden coasters with simple geometric patterns. It’s a great way to practice basic design and cutting skills.

- Keychains: Create personalized wooden keychains for yourself or as gifts. Experiment with different wood types and engrave names or patterns.

- Picture Frames: Make wooden picture frames by cutting and engraving. Customize them with meaningful quotes or designs.

ii. Intermediate Projects

- Laser-Cut Chess Set: Design and cut a chess set with intricate, laser-engraved details on the pieces. It’s a challenging but rewarding project.

- Wooden Puzzle: Craft wooden puzzles with interlocking pieces. They can be simple or complex, depending on your skills.

- Laser-Cut Clock: Design a unique wooden wall clock with precision-cut numbers and patterns. Experiment with different wood types for a variety of looks.

iii. Advanced Projects

- Furniture: Take on ambitious projects like laser-cut wooden tables, chairs, or bookshelves. The precision of laser cutting allows for intricate designs in furniture.

- Wooden Gears and Mechanisms: Create intricate wooden gears and mechanical systems. These projects demand a deep understanding of engineering and woodworking.

- Wooden Models: Craft intricate models of buildings, vehicles, or other objects with laser-cut wooden parts. This is a complex, detail-oriented endeavor.

iv. Personalizing and Customizing Projects

- Personalized Gifts: Whether it’s engraved cutting boards, custom wooden boxes, or monogrammed coasters, personalizing your projects adds a unique touch.

- Nameplates and Signs: Create nameplates for your home or office door, or design wooden signs for special events like weddings.

- Custom Wooden Jewelry: Craft your jewelry using laser-cut wooden pieces, and personalize them with unique designs and patterns.

v. Showcasing Woodworking and Laser Cutting Together

- Laser-Cut Inlays: Incorporate laser-cut wooden inlays in your traditional woodworking projects. Inlays add depth and intricate details to wooden surfaces.

- Combining Materials: Blend laser-cut wooden components with other materials like metal, glass, or acrylic to create unique, mixed-media pieces.

- Functional Art: Design functional art pieces, such as wooden lamps or sculptures, that showcase the seamless integration of woodworking and laser cutting.

9. Laser Cutter Troubleshooting and Maintenance

Maintaining and troubleshooting your wood laser cutter is essential for ensuring its longevity and optimal performance. Let’s explore these aspects to keep your laser cutter in top shape.

i. Common Issues and Solutions

- Uneven Cuts: If your laser cutter is producing uneven cuts, it may be due to misaligned mirrors or a dirty lens. Check and realign the optical path, and clean the lens regularly.

- Charring or Burning: Excessive charring or burning can result from incorrect settings. Adjust the power and speed settings for your wood type, and ensure proper ventilation to remove smoke and fumes.

- Inconsistent Engraving: If your engraving results are inconsistent, the problem might be related to varying wood thickness. Adjust the focus or use auto-focus features to maintain consistent engraving depth.

- Excessive Noise: Unusual noises during operation can be a sign of worn or loose components. Inspect the laser cutter for loose belts, bearings, or other parts, and replace or tighten them as needed.

ii. Routine Maintenance Tasks

- Cleaning Optics: Regularly clean the laser lens and mirrors to remove dust and residue. Use lens cleaning solutions and lint-free wipes for this task.

- Checking Belts and Rails: Ensure that the belts and rails are clean and in good condition. Lubricate them as recommended by the manufacturer to prevent excessive wear.

- Cooling System Maintenance: Regularly inspect the cooling system, including water or air filters. Ensure the coolant is at the proper level and free of contaminants.

- Ventilation System: Clean or replace filters in the ventilation system as needed to maintain effective fume and smoke extraction.

ii. Extending the Lifespan of Your Wood Laser Cutter

- Proper Material Selection: Choose materials suitable for laser cutting to prevent excessive wear and tear on the machine.

- Control Temperature and Humidity: Maintain stable environmental conditions in your workspace. Fluctuations in temperature and humidity can affect the laser cutter’s performance.

- Safety Precautions: Follow safety guidelines and precautions to avoid accidents that can damage the laser cutter.

- Regular Testing: Periodically conduct test cuts and engravings to ensure the machine is operating at its best. Adjust settings as needed.

iv. Professional Servicing Options

- Manufacturer’s Service: Most manufacturers offer professional servicing. Regularly scheduled maintenance visits from the manufacturer’s technicians can ensure the machine’s longevity.

- Local Service Providers: In areas with a high concentration of laser cutter users, you might find local service providers who specialize in laser cutter maintenance and repair.

- DIY Repairs: For minor issues, you can perform some repairs yourself if you have the necessary skills and knowledge. However, be cautious, as DIY repairs can void warranties or cause further damage.

Incorporating these troubleshooting and maintenance practices into your laser cutter’s care routine will help prevent issues, extend its lifespan, and ensure consistent, high-quality results in your woodworking projects. Remember that regular maintenance is an investment in the longevity and reliability of your laser cutter.

10. Resources and Further Learning

Exploring further resources and learning opportunities is vital for mastering the art of wood laser cutting. Let’s delve into some valuable avenues for enhancing your knowledge and skills.

i. Online Communities and Forums

- Reddit’s Laser Cutting Community: The /r/lasercutting subreddit is a bustling hub of laser enthusiasts. Here, you can seek advice, share your projects, and troubleshoot issues with experienced laser cutters.

- CNC Zone: This dedicated forum covers various laser technologies, including wood laser cutting. It’s an excellent place to connect with fellow laser enthusiasts and gain valuable insights.

- Maker Spaces and Fab Labs: Many cities have maker spaces or fab labs where you can access laser cutting equipment and connect with like-minded individuals.

ii. Recommended Books and Publications

- “Laser Cutting Guide for Manufacturing” by Charles Caristan: This book provides a comprehensive guide to laser cutting technology, including principles, processes, and applications.

- “Laser Cutting for Fashion and Textiles” by Laura Berens Baker: If you’re interested in laser-cutting textiles or fashion design, this book offers valuable insights and creative ideas.

- “Laser Cutting and 3-D Printing for Railway Modellers” by Timothy J. Horton: Ideal for model railway enthusiasts, this book explores laser cutting and 3D printing techniques for model making.

iii. Training Courses and Workshops

- Online Laser Cutting Courses: Websites like Udemy and Coursera offer various laser cutting courses, from beginner to advanced levels, allowing you to learn at your own pace.

- Local Workshops: Check with local makerspaces, colleges, or woodworking schools. They often host workshops on laser cutting where you can gain hands-on experience.

- Laser Cutter Manufacturer Training: Many laser cutter manufacturers offer training programs on the operation and maintenance of their specific machines.

iv. Wood Laser Cutter Suppliers and Manufacturers

- Epilog Laser: A renowned manufacturer of laser cutters and engravers, Epilog provides an extensive range of laser machines suitable for various applications.

- Trotec Laser: Trotec offers a wide selection of high-quality laser cutting and engraving machines, known for their precision and reliability.

- Universal Laser Systems: Universal Laser Systems specializes in advanced laser technology, including materials processing systems and laser workstations.

- Full Spectrum Laser: This manufacturer provides a variety of laser cutters and engravers, catering to hobbyists, makers, and professionals.

11. Conclusion

In conclusion, the world of wood laser cutting offers a realm of possibilities for woodworking enthusiasts, from beginners to seasoned professionals. By exploring various laser cutting techniques, maintenance and troubleshooting practices, and a wealth of resources, you can embark on a creative journey like no other.

The common issues and solutions provided can guide you in overcoming challenges that may arise during your projects. Routine maintenance tasks are vital for preserving the longevity of your wood laser cutter, ensuring it operates at its best. Extending the lifespan of your machine and seeking professional servicing options when needed are essential for maintaining its efficiency.

Furthermore, the plethora of resources and avenues for further learning empowers you to broaden your horizons in the world of wood laser cutting. Online communities, recommended books and publications, training courses, and workshops are all at your disposal, helping you refine your skills and knowledge.

Intricate projects await, from beginner-level creations like coasters and keychains to advanced endeavors like furniture-making and complex mechanical systems. Personalizing and customizing your projects adds a unique touch, making each creation a one-of-a-kind masterpiece.

As you explore these opportunities and resources, your woodworking and laser cutting journey will not only enhance your craftsmanship but also unlock your imagination. The fusion of technology and tradition in laser cutting allows you to turn your visions into tangible works of art, and with ongoing learning and dedication, the possibilities are endless. So, embark on this exciting adventure and bring your woodworking and laser cutting dreams to life.

12. Glossary

| Term | Definition |

|---|---|

| Laser Cutter | A machine that uses a high-powered laser to cut or engrave materials, including wood. |

| Laser Beam | The concentrated beam of light generated by the laser source for cutting or engraving. |

| CO2 Laser | A type of gas laser commonly used in laser cutters for wood. It produces a laser beam in the infrared spectrum. |

| Laser Source | The component that produces the laser beam. It’s typically a CO2 laser tube. |

| Engraving | The process of using the laser to create patterns, text, or images on the surface of wood without cutting through it. |

| Vector Cutting | Cutting along vector paths defined by vector graphics, typically used for creating precise shapes and intricate designs. |

| Raster Engraving | Engraving by using a series of closely spaced lines, producing a shading effect in the engraved area. |

| 3D Engraving | Creating three-dimensional textures and reliefs on wood using the laser to produce varying depths. |

| Inlay | A technique where precise cut pieces of wood are fitted into corresponding recesses in a base wood piece, creating intricate patterns. |

| Marquetry | The art of inlaying small pieces of different types of wood to form decorative patterns. |

| Joinery | The method of joining pieces of wood together to create a structure. Laser-cut joints can be highly precise. |

| Laser Optics | Components like lenses and mirrors used to focus and direct the laser beam to the workpiece. |

| Cutting Area | The maximum dimensions of the workpiece that a laser cutter can accommodate. |

| Ventilation System | The system that removes smoke, fumes, and debris produced during laser cutting to maintain a safe working environment. |

| Exhaust System | A part of the ventilation system that carries away smoke and fumes from the cutting area. |

| Laser Safety Glasses | Protective eyewear designed to shield the eyes from the intense laser light. |

| Laser Safety Interlocks | Safety features that prevent the laser cutter from operating when safety enclosures are open or under hazardous conditions. |

| Emergency Stop Button | A button that immediately halts the laser cutter’s operation in case of an emergency. |

| Laser Cutting Software | Specialized software for designing, editing, and controlling laser cutting and engraving processes. |

| Materials Compatibility | Understanding which materials can be safely and effectively cut or engraved with a laser cutter. |

| Engraving Depth | The level to which the laser engraves the wood’s surface. |

| Laser Focus | Adjusting the laser’s focus to ensure precision in cutting and engraving. |

| Test Cuts | Trial runs on a small piece of material to determine the optimal settings for a specific project. |

| Focal Length | The distance from the lens to the point where the laser beam is most focused. |

- Mastering Wood Laser Cutters: A Comprehensive Guide for Woodworkers - October 14, 2023

- The Best Laser Cutters Under $1000 - August 24, 2023

- Best Wood Laser Cutter Under $500 - August 14, 2023