Wood milling, an age-old practice integral to woodworking, transforms timber into a canvas of infinite possibilities. From the shaping of the earliest tools to the crafting of contemporary furniture, wood milling has evolved, yet its essence remains unchanged. It’s the art of turning nature’s bounty into objects of function and beauty.

1. A Historical Snapshot of Wood Milling

Wood milling, much like a river cutting through the landscape, has carved its path through history. From simple hand-powered mechanisms to sophisticated computer-controlled marvels, the journey of wood milling mirrors humanity’s ingenuity and its continuous strive towards efficiency and precision.

2. What Is Wood Milling?

At its core, wood milling is the process of shaping raw lumber into finished products. It’s an intricate dance between man, machine, and wood, where each step, from the initial cut to the final polish, is a deliberate stroke of craftsmanship.

I. The Transformation Journey

Starting as a rugged natural resource, wood undergoes a metamorphosis. Through milling, this raw material is gradually refined, revealing its inner beauty and potential, ready to be moulded into the myriad forms envisioned by its crafters.

3. The Milling Process: How Is Wood Milled?

The milling process is a symphony of steps, each crucial to the integrity of the final product. It’s a journey from the forest to the workshop, an alchemy that turns raw logs into treasured artifacts.

Main Stages of Wood Milling

I. Selecting the Timber

Before the milling begins, one must choose the right timber. This initial decision shapes everything that follows.

II. Sawing the Logs

The roar of the saw is the first act of transformation, as logs are cut to manageable sizes.

III. Drying the Milled Wood

Like aging fine wine, wood must be dried to achieve the perfect balance of strength and workability.

IV. Planing to Thickness

With each pass through the planer, the wood becomes more uniform, a step closer to its final form.

V. Profiling and Detailing

Here, the wood begins to show its final shape, detailed and defined, ready for its ultimate purpose.

4. What Are the Different Types of Milling Machines Used in Woodworking?

The machines used in woodworking are as varied as the products they create. Each has its role, its specialty, and its place in the workshop.

I. Handheld Routers

Compact and versatile, handheld routers are the artist’s brush in the world of wood milling.

II. Benchtop Milling Machines

Benchtop milling machines bring precision and stability to the workshop, essential for detailed work.

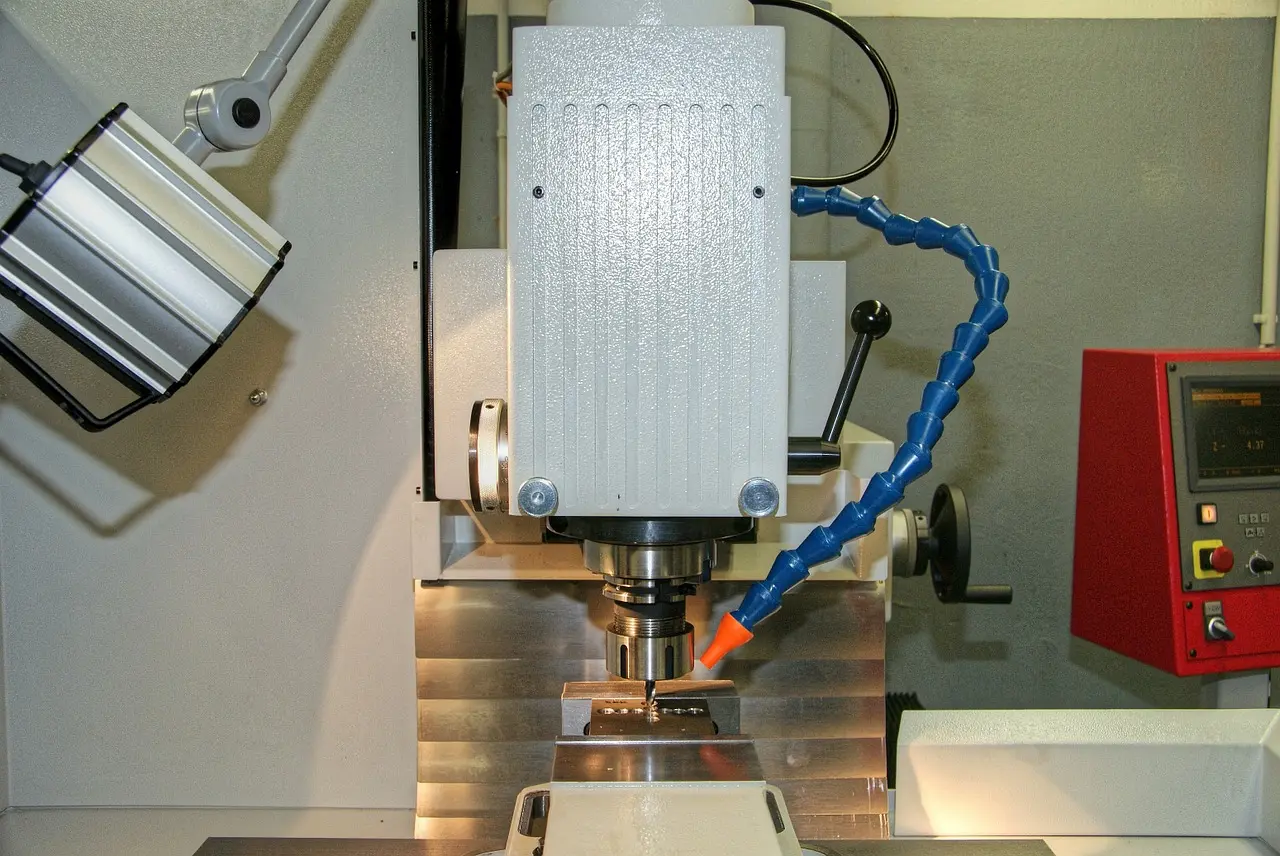

III. CNC Milling Machines

The pinnacle of modern woodworking technology, CNC machines offer unparalleled precision and complexity in milling.

IV. Planer Thicknessers

Planer thicknessers are the workhorses of the milling process, transforming rough lumber into smooth, even boards.

5. Understanding the Anatomy of a Milling Machine

The question is what is a milling machine?

A milling machine, regardless of its type, is an assembly of purpose-driven parts, each essential for transforming wood from raw to refined.

Main Parts of a Milling Machin

- The Cutterhead: The heart of the machine, where wood is shaped and smoothed.

- The Bed: A stable foundation that guides the wood on its transformative journey.

- The Fence: A crucial guide that ensures precision and consistency in every cut.

6. What Are the Key Techniques in Wood Milling?

Mastering wood milling techniques is akin to learning a language. Each technique is a word, each stroke a sentence in the story of creation.

Essential Milling Techniques

I. Edge Milling

A technique focused on creating perfect edges, essential for joinery and fine detailing.

II. Face Milling

This differs from edge milling in its focus on the broad surfaces of the wood, preparing them for further work or finishing.

Edge Milling: What Is It and When Is It Used?

Edge milling is about precision. It’s used when the edges of a workpiece must join seamlessly with others, a critical step in many woodworking projects.

Face Milling: How Does It Differ from Edge Milling?

Face milling, in contrast, is all about the surface. It’s where the wood’s face is smoothed and prepared for finishing touches.

7. What Are the Benefits of Using a Helical Cutterhead?

Helical cutterheads are a marvel, offering smoother cuts and a quieter milling experience, enhancing both the process and the product.

8. What Types of Wood Are Best for Milling?

The suitability of wood for milling is as much about its species as it is about the craftsman’s intent. Each type of wood brings its unique personality to the milling table.

Ideal Wood Types for Milling

- Softwoods: Pine, Cedar, and Spruce

- These woods are pliable and easy to work with, making them ideal for beginners.

- Hardwoods: Oak, Maple, and Walnut

- Hardwoods offer a sturdier end product, prized for its durability and rich textures.

- Engineered Woods: Plywood and MDF

- Consistency is the hallmark of engineered woods, providing uniformity in milling.

- Exotic Woods: Teak, Mahogany, and Rosewood

- Exotic woods bring an international flair to projects, each with distinctive grains and hues.

Challenges and Easiness in Milling

I. Which Wood Species Is the Easiest to Mill?

Typically, softwoods like pine are more forgiving and easier to mill.

II. What Are the Challenges of Milling Hardwood?

Hardwoods require sharper tools and more patience but reward with unmatched beauty.

9. Advantages of Milling in Woodworking

The benefits of milling are as numerous as the grains in a piece of wood, each adding value to the woodworking process.

Advantages

- Precision

- Milling allows for exact cuts, ensuring pieces fit together perfectly.

- Customization

- It opens up a world of design possibilities, tailored to specific requirements.

- Efficiency

- Modern milling techniques streamline the woodworking process, saving time and resources.

I. Wood Milling Applications: Who Uses This Process?

Wood milling is not just for the solitary woodworker; it’s a vital process in numerous industries, each with its specialized applications.

Industries and Applications

- Furniture Making: Crafting everything from sturdy tables to delicate chairs.

- Construction: Milling wood for framing, flooring, and paneling.

- Musical Instruments: From the resonant bodies of guitars to the precise keys of pianos.

- Boat Building: Milling wood to create strong, watertight vessels.

10. Essential Considerations for Efficient Wood Milling

Efficient wood milling is not just about the right tools; it’s about approach, knowledge, and attention to detail.

Considerations and Common Mistakes

- Wood Selection: Choosing the right type of wood for the project at hand is paramount.

- Machine Calibration: Ensuring machines are calibrated for precision to avoid errors.

- Milling Environment: A well-organized, safe, and clean environment contributes to efficient milling.

- Avoiding Common Mistakes: Learning from others’ experiences can prevent costly errors in your own work.

11. The Step-by-Step Guide to Milling Wood

Milling wood is a step-by-step process, each stage building upon the last, culminating in a finished piece that stands as a testament to skill and patience.

The Steps

- Preparation: Before the milling begins, preparing the wood and the workspace is crucial.

- Milling: The actual process of cutting, shaping, and refining the wood.

- Finishing: The final touches that protect the wood and showcase its beauty.

- Preparing the Wood: The preparation of the wood is where the vision for the final piece begins to take shape.

I. Safety Tips During Wood Milling

Safety in milling cannot be overstated; it’s the foundation upon which all else rests.

II. Design Considerations for Milling Wood

Design considerations guide the milling process, ensuring that the final product not only looks good but also serves its intended function.

12. Cost Analysis of Wood Milling

The cost of wood milling is influenced by a variety of factors, from the type of wood to the complexity of the project.

Factors Influencing Cost

- Type of Wood: Some woods are more expensive to mill due to their hardness or rarity.

- Milling Complexity: More intricate designs require more time and skill, increasing the cost.

- Professional Milling and Machine Costs

- Professional Services: The expertise of professional millers is often worth the cost for complex projects.

- Machine Running Costs: The maintenance and operation of milling machines factor into the overall cost.

13. Top Milling Machines for Woodworking: A Buyer’s Guide

Choosing the right milling machine is a significant decision, one that can influence the quality and scope of a woodworker’s projects.

Criteria for Selecting Milling Machines

- Quality of Build: A well-built machine will provide years of reliable service.

- Versatility: The ability to handle a wide range of projects adds value.

- Ease of Use: A user-friendly machine reduces the learning curve and enhances productivity.

14. Alternative Wood Shaping Techniques

While milling is a cornerstone of woodworking, there are other techniques available, each with its own set of advantages.

- Hand Carving: For those who prefer a more hands-on approach, carving offers a personal touch.

- Turning: Ideal for creating symmetrical, rounded objects like bowls and spindles.

- Sawing: Sometimes a simple saw cut is all that’s needed to achieve the desired effect.

Comparison with Milling: While these methods can be more labor-intensive, they offer alternatives that can be better suited to certain projects or artistic visions.

15. Conclusion

Milling is more than just a woodworking process; it’s a bridge between raw material and finished art. As we look to the future, the evolution of milling stands as a testament to our enduring relationship with wood—a relationship built on a foundation of skill, precision, and creativity.

- A Comprehensive Guide to Woodworking Tools: Over 35 Different Tools - January 5, 2024

- What is Woodworking? The Art of Wood in a Nutshell - January 4, 2024

- The Benefits of Using Wood in Plumbing Fixtures and Decor - December 29, 2023