To Make woodworking smooth, some dedicated equipment is needed.

A woodworking vise is an essential piece of equipment a woodworker must possess.

A vise is generally attached to a fixed location, such as a workbench. Because they might damage the wood being handled, the jaws are typically made of hardwood or steel that locks the object in place. The bench vise’s wooden jaw protects the object from harm.

There are two jaws for gripping the item and a screw arrangement for adjusting the tightness of the work. However, because there are so many different sorts of vises, you’d have to understand precisely what each woodworking vise can accomplish for you.

So Let’s Dive In!

Woodworking Vise 2023

We have covered all the major aspects of a woodworking vise that are essential to know. Here is a detailed woodworking vise guide that’ll answer all your queries.

- What does a woodworking vice do?

- Types of woodworking vises

- What vice do I need for woodworking?

- How do you install a woodworking vise?

- Do carpenters use vise?

- Where should you position a workbench vise?

- How do you secure a vise to a workbench?

- Do I need a tail vise?

- Why is the bench vise mounted on the edge of the workbench?

- What clamping position should be considered when mounting a vise on a workbench?

- What you should look for in a good vise?

- Final thoughts

What does a woodworking vice do?

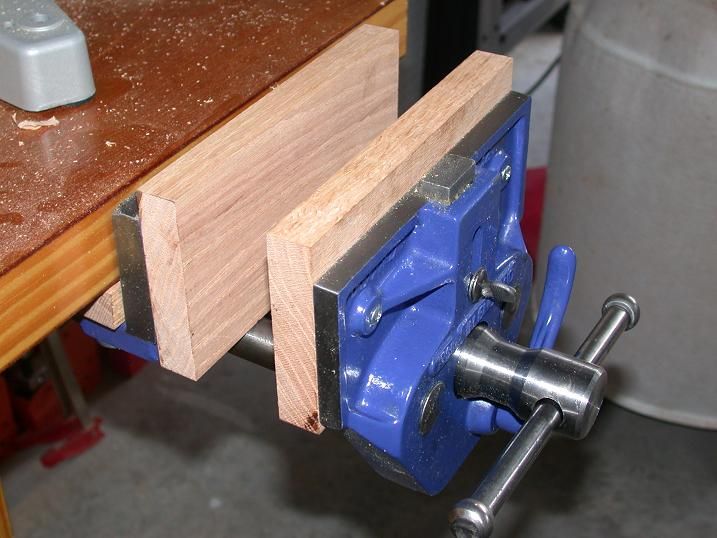

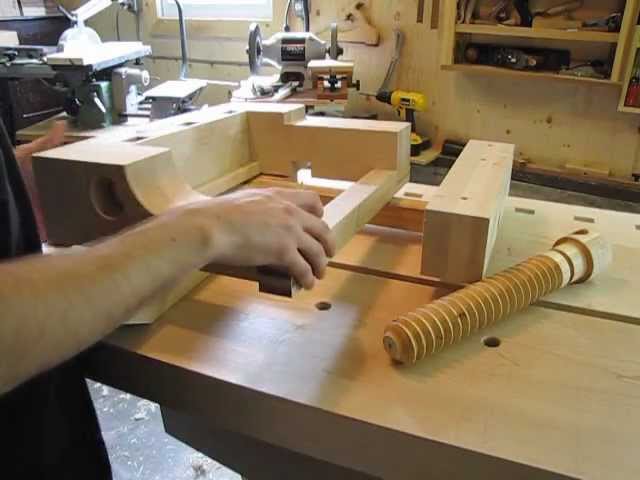

A woodworking vise is a massive instrument utilized to fasten securely significant sections of wood. This style of the vise is commonly used by experienced furniture makers, production units, or anyone tackling a woodworking job. Many woodworking vise types are available nowadays. A woodwork vise is often attached to the workbench’s underside. This allows the vise’s jaws to be square with the bench area.

Types of woodworking vises

Here are some vice types that you may utilize in an apt manner. Each has a unique function & its important to learn what fits your purpose best before deciding to invest in one.

Quick Release

A quick-release woodworking vise accomplishes precisely what it says on the package. When you’re through with the work, open the split nut to release it quickly. Instead of the many twists required with many alternative kinds of vises, you may now remove the jaws with a simple lever rotation. As a result, this sort of woodworking vise is often employed in mass manufacturing tasks with repeated procedures. In addition, the function of the quick-release splitting nut enhances the pace of movement significantly.

Woodcraft Vise

This type of woodworking vise is equipment that is often seen in the household. Unlike carpentry vises, which are usually more extensive, the woodcraft vise is simpler to handle and transport.

For fastening tiny wooden pieces, we generally utilize a woodcraft vise. Even though amateurs and maintenance specialists commonly use this style of the vise, it is also found in so many industrial woodworker companies.

This woodworking vise is also helpful in fixing different wooden home objects that require bonded parts to be clamped securely.

Pattern Maker’s Vise

A pattern maker’s vise is a precise instrument used in woodworking for a variety of tasks. This large wood vise can spin, twist, and pivot, making it a flexible tool for clamping a workpiece in any target place. The pattern maker’s vise has few variants, yet it is an essential tool for every craftsman who performs a wide range of carpentry tasks. A Diy wagon vise is also common.

Wood Bench Vises

This is the equipment that every craftsman has on their workstation. This type, however, is more common in the United States than in the United Kingdom. The distinction between this vise and various vises is that we do not attach it somewhere else but rather make it a permanent component of the workstation. We firmly connect the jaws and lever to the worktop and will not remove them. There are several types of woodworking workbench vise.

What vice do I need for woodworking?

Face vises for workbench are mainly intended for gripping hardwood components while performing duties such as drilling and cutting.

Wood is the typical element. A vise for wood comprises a moveable forward jaw attached to a broad, rectangular shaft that moves in and out of a corresponding slot. The jaw is powered by wooden bench screws, held firmly and precisely positioned by the frame. From underneath, the entire device is attached to the benchtop.

Woodworkers vise is the current version of the hardwood face vise. These are also flat to the bench surface and are completely metal (except for wooden jaw guards that avoid harm if the metal jaws are clamped straight into hardwood functional objects).

Many hobbyists who create their workbench build a woodworking vise, generally utilizing a combination of off-the-shelf metal drive components with shop-made hardwood jaws and attachment components such as blocks and guides also woodworking front vise is also good.

Woodworker’s vise is available in nearly any dimension, with jaws varying from five inches broad to twelve inches more than, with a most extraordinary extending capability ranging from three to sixteen inches or over. The dimension users require is determined by the length of the material they want to utilize for most of their tasks.

How do you install a woodworking vise?

Here we have laid out some easy-to-follow instructions.

Step 1: Take Your Jaw Measurements

Hold the wood vise and slide in the place where you intend the grip to be. While the woodworking front vise is in position, take approximate measurements of the jaw. Remember to leave enough space for the upper section to be planed level with the benchtop in the bottom.

Step 2: Create the Roughly Shaped Jaw (s)

We used the side of the benchtop as an outside jaw and the border of the benchtop as an inside jaw, but you can do it in a variety of methods, so choose what goes better for you! First, cut the enlarged jaw to depth and diameter, but allow somewhat excess so you may fine-tune it afterward.

Step 3: Take the Vise Out of the Clamps

You may remove the woodworking vise now that you have done your measuring and the jaw(s) removed. Follow this with the following step.

Step 4: Take Off the Back Plate

Disconnect the primary screw and guiding poles from the rear panel. Then proceed further in the task. Here comes the next step.

Step 5: Unscrew the Quick Release Nut.

Take the quick release screw, but Know HOW IT Fits; I recommend snapping a photograph of its orientation to ensure it gets down properly; otherwise, the woodworking vise will not function as designed.

Loosen the vise plate’s primary screw and guide rods. You may detach the significant component from the plate if you have a regular vise rather than a fast discharge.

Step 6: Attach the Vise Plate

Reinstall the woodworking vise plate in its original position. To guarantee effective functioning of the vise, provide a gap from the border of the benchtop to the surface (do not flush install). Identify the center of the attachment slots on the plate using a pencil. When the holes are critical, We usually utilize a punch or an awl to provide the drill bit with a strong beginning position and keep it from straying. Pre-drill all of the indicated spots and secure the plate with the vise’s appropriate length screws.

Step 7: Attach the Vise Hardware to the Front Jaw

Set the jaw in the mounting position, being watchful to leave the upper border of the jaw clear of the woodworking front vise of the bench. Label the center of the openings in the vise attachment plate where the poles and screws pass through the forward jaw using a pen. Drill the openings somewhat more extensive than needed to accommodate the rods and screw, allowing for some wiggle room to correct any minor errors in your measurements. Next, insert the vise equipment through the forward jaw face and note the position of the screws that will be used to secure the vise equipment to the front jaw. Strike with a punch once more, then pre-drill and insert the screws. The intricate work is now finished!

Step 8: Insert the vise equipment into the front jaw

If you’re utilizing a quick release woodworking vise, slightly insert the central screw and poles into the openings on the vise installation panel (enough to keep them in position). Replace the quick release nut (in the appropriate direction) and tighten the vise back in place. Next, replace the rear plate over the central screw and poles. This piece will save you from accidentally overburdening the vise and letting it come off. Next, insert the handles and tighten the vise in all manner.

Step 9: Plane Flush

Level the forward and back (optional) jaw(s) flat on the benchtop. WE’RE GETTING CLOSE to complete the installation.

Step 10: Apply Finish

Complete the jaw(s) and handle with your desired will and task. Examine the vise’s movement to verify that everything is moving smoothly. If that’s the case, you’re all done; Appreciate YOUR Awesome VISE!

Do carpenters use vise?

Yes, craftsmen utilize vises for a variety of applications while dealing with wood. For example, a woodworkers vise is a kind of vice that is mainly used to clamp hardwood without causing damage to the exterior securely.

When doing operations such as cutting, drilling, or construction, wood is frequently fastened. This is done so that the operator may maintain both hands clear and away from the substance while applying it, and a woodworking vise is an excellent instrument to utilize in this circumstance.

The majority of woodworking bench vises are intended to be firmly attached to a worktop. Therefore, they are often mounted beneath the workbench, with the top side of the jaws parallel with the workbench’s area.

Where should you position a workbench vise?

It is not hard to mount a bench vise correctly, but it might have a long-term impact on the effectiveness of your clamp. For example, a fixed vise is frequently positioned in the center of a tabletop. There are many workbench vice uses.

Also, there are many s Bench vises retain stronger when you press towards them, with the bench’s weight behind the object. As a result, face vises are often located on the bench’s left side. While slicing workpieces (below), a left-side clamp allows you to grasp onto the offcut while the main component is securely held in the jaws, leading in a neater cut. There are many workbench vise types.

However, you can place a vise anywhere it is suitable for you. Even more significant, attach two vises to your workbench. We favor a face vise on the left, and on the right, we prefer a tail vise.

How do you secure a vise to a workbench?

To begin, check and label the attachment apertures. Put the woodworking vise where you desire them, and then indicate the anchoring openings with a pencil. It’s worth noting that certain vises arrive with a fastening guide. If you intend to utilize the supplied template, make sure that it correctly fits the vise foundation since they do not often meet up perfectly.

Drill the attachment apertures utilizing an adequately sized tool. When operating on plywood, be cautious not to exert too much force since this might lead the foundation to split when you burst through.

Insert a screw over the openings on your vise foundation as testing. If the washer is too large, you may quickly smooth down a piece of the surface using a bench sander or steel file for a great match.

Put the vise over the openings and insert the nut (with a washer). If you have a measurement problem, be sure you utilize the adjusted washers.

Insert a washer, lock washer, and nut on the bottom of one opening and manually compress. Repeat for the remaining bolts.

Secure every bolt with a swivel wrench and an ordinary wrench (to retain the nut). While dealing with any wood, you’ll require a good fitting, but don’t overtighten. Make a second pass around the bolts to verify they are equally adjusted.

If you’ve decided to use a jawless face vise or a bigger flatter jawed opening vise, you’ll require wood to safeguard your work. So, what is the finest wood for a hardwood jaw vise? Examine the following choices:

- Hard maple is generally the ideal choice since it has long endurance, a solid grip on hardwoods, and a gentle line on less thick woods.

- If your tasks require softwoods such as 24 or other sized timber, use a sapless cutting of grade pine.

- Finally, if you prefer a softer texture, consider interface attaching a felt or mar-free rubber.

Do I need a tail vise?

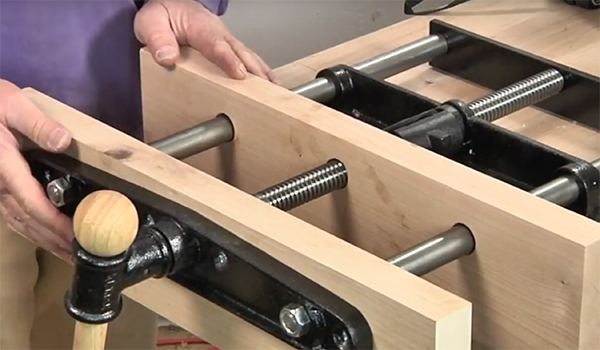

As it is often known, the end or tail vice is incorporated into the bottom of a bench (usually typically the right-hand end) and may be utilized to attach flat surfaces to the bench among its jaws. Thus, the benchtop serves as the inner jaw of the flush-mounted tail vise, and the workbench nut tightens the moveable jaw against it. People often compare face vise vs tail vise.

The tail vise is a considerably more versatile instrument than it appears. It differs from conventional vises in that it has a rectangle opening cut into its front, which is matched with a sequence of other openings along the edge of the workbench.

The primary cause a conventional tail vise is so beneficial is the precise spacing it provides on top of your bench. This allows you to securely fasten chair legs or another lengthy item that has to be kept while you operate on it from one end. You also get equipment storage on both edges of the work.

In our instance, the tail vise also includes dog holes, allowing us to attach planks up to seven feet in length, which is more significant than our workbench, and have them maintained along the bottom, besides a bit of space. That type of stability is just not available with an end-mounted face vise.

Why is the bench vise mounted on the edge of the workbench?

When placing your woodworker’s vise, the fixed jaw should extend just over the border of the tabletop. This enables you to fasten more extended parts that will dangle below the table surface.

Right-handed people generally choose to install the woodworking vise at the top-right edge of the workbench or reloading table. (For lefties, use the left area.) Put a rectangular piece of metal between the bench and vise or beneath the bench for further support. There are various types of woodworking benches available in the market.

What clamping position should be considered when mounting a vise on a workbench?

The woodworking vise must be set up to keep a lengthy item straight in the jaws without obstructing the worktop. Considering you’re right-handed, conventional installation places would be to the side of your bench’s top corner or the right side of your work surface.

Carvers, as well as others who fasten many surface materials like doorways and huge boards, may likely discover the end location most beneficial. The forward surface is perhaps the finest choice for general-purpose tasks.

Ensure that the clamp does not impede the leg or covers of the bench. Note that the vice will have hardwood jaw guards that protrude over the top of the vice. Many individuals choose to have the extremities of the jaw protectors level with the edge of the workbench, so keep that in mind while deciding where to put your vice.

What you should look for in a good vise?

To guarantee that you wind up with the most delicate equipment for your requirements, you must first conduct your research. Whenever you place your order, examine the below things.

Material

The majority of high-quality vises are made of cast iron. This substance has an extreme mechanical toughness, allowing it to bear the significant clamping strain. Because of its hardness, you may also hammer on its surfaces.

Steel-constructed vises are very famous since they are incredibly robust and lasting. However, steel, unlike cast iron, may bend when subjected to extreme compression. Steel vises are often less costly as a consequence. Nonetheless, because woodworking operations do not need much force to attach workpieces, a good steel vise can last a lengthy period. Woodworkers often think of end vise vs front vise.

Jaws that can be replaced

Consider purchasing a woodworking vise with interchangeable jaws. It is because prolonged pushing decreases the jaw’s grip. A vise with interchangeable jaws enables you to prolong the life of the vise without replacing the complete machine.

Jaw Dimensions

This relates to the width of the gripping area of a jaw. The optimal jaw length for moderate to medium-duty applications must be around five and seven inches. Heavy-duty applications generally need jaw diameters ranging from 8 to 10 inches.

Jaw Expansion

This is the space across completely extended jaws. Therefore, the breadth of the substances you may operate with is determined by the jaw space. As a result, if you want to work on more prominent objects, you should seek a vise with a greater jaw size.

Throat Diameter

This is the space between both the tip of the jaws and the screw mechanism’s edge. The throat depth influences how far a component may be pushed into the vise while clamping it. A deeper throat depth enables you to grip a big object more firmly.

Rotation of the Swivel

Excellent woodworking vise generally includes a revolving swivel, which improves your job much more straightforward. For example, rather than hunching over to change the vise’s position, you may easily rotate it so that it approaches you.

Rapid Release

It’s exhausting to continually screw a woodworking vise in and out to readjust your workpiece. It also leads to a significant amount of wasted time. Instead, imagine getting a vise with a fast working or rapid-release function to improve your effectiveness and production. With a rapid turn of the lever, you’ll be able to release and shut the jaws.

Warranty

Vises aren’t equipment that needs to be replaced each day. As a result, you need to be sure that the device you purchase will endure for a lengthy period, and that is why you must always choose alternatives that have a guarantee. A guarantee is also a qualitative indication since it demonstrates that the producer believes in the longevity of their goods.

Final thoughts

A vise is the focal point of every carpentry workplace since it is used in nearly all tasks. It is generally understood that the condition of your vise impacts the content of your job as well as your efficiency.

However, not all woodworking bench vise on the marketplace will make ideal workplace companions. As a result, you must conduct thorough research to determine the appropriate solution for your goals and money. The smooth edges of carpentry vices’ jaws are crucial features that make them excellent for wood fastening. When fastened, the flat surfaces prevent the wood from being damaged or indented.

Most furniture makers will consider a face vise helpful, and nearly as many will rapidly come to appreciate the benefits of a tail vise if they don’t already. The strong engineer’s vise is essential for anybody who deals with metal—which, by the meantime, encompasses nearly every carpenter when it refers to grinding and working with various problems.

- A Comprehensive Guide to Woodworking Tools: Over 35 Different Tools - January 5, 2024

- What is Woodworking? The Art of Wood in a Nutshell - January 4, 2024

- The Benefits of Using Wood in Plumbing Fixtures and Decor - December 29, 2023